이메일 형식 오류

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

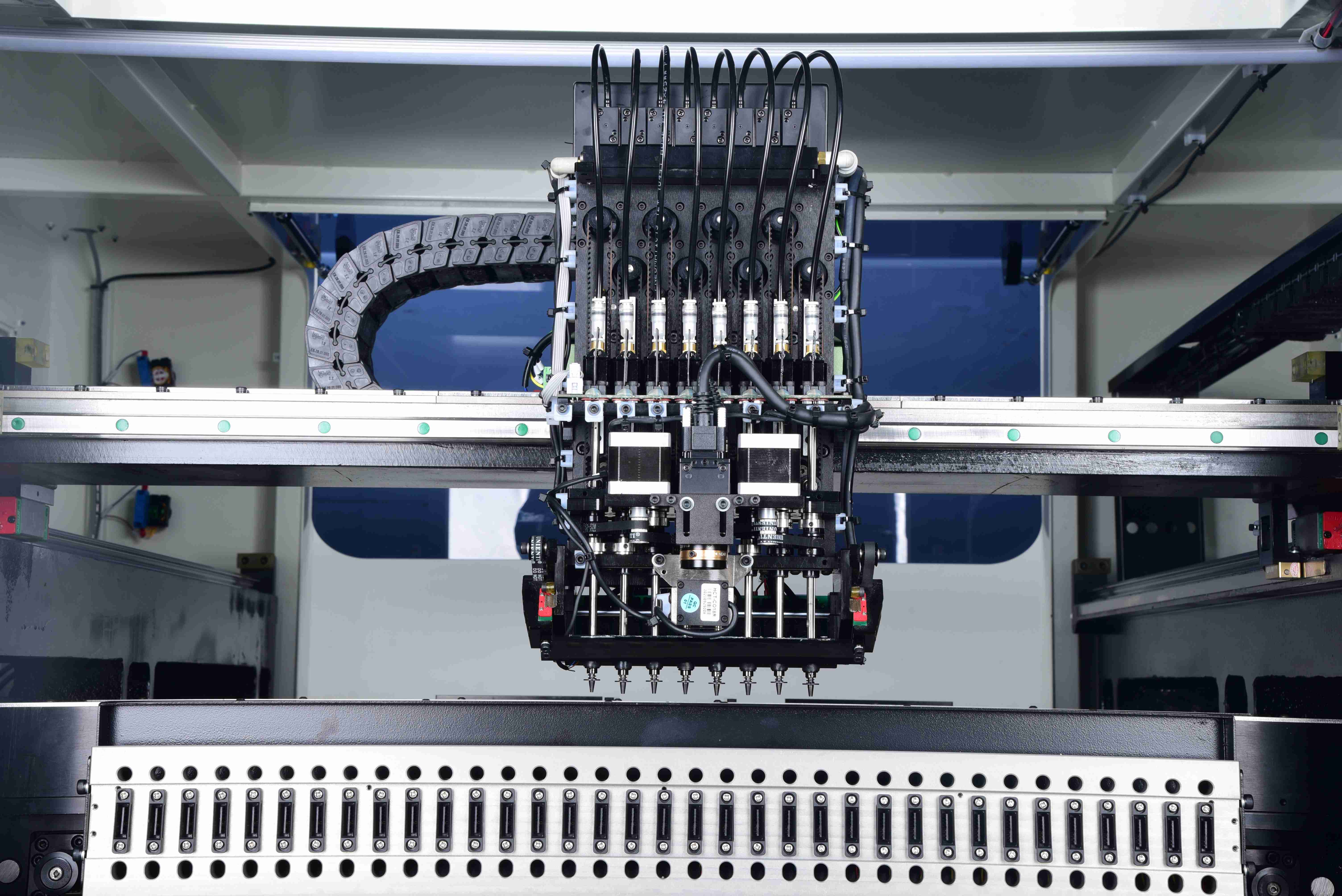

LED Display SMT Pick and Place Machine

LED displays have gradually become an integral part of numerous applications, including advertising, retail, and entertainment. To keep pace with the increasing demand for high-quality LED displays, manufacturers rely on advanced machinery such as the LED display SMT pick and place machine. This article aims to provide an in-depth description of this sophisticated device, highlighting its features, benefits, and working principles.

· Understanding LED Display SMT Pick and Place Machine

1. Overview:

The LED display SMT pick and place machine is a state-of-the-art piece of equipment designed to streamline and enhance the assembly process of LED display circuit boards. This machine incorporates advanced robotic technologies and computer-controlled systems, revolutionizing the production line.

2. Key Features:

- High Precision: The LED display SMT pick and place machine is equipped with a precise positioning system, ensuring accurate component placement on circuit boards.

- High Speed: With a rapid pick and place mechanism, this machine can achieve a high rate of board assembly per hour, significantly increasing production efficiency.

- Versatility: Designed to handle various types and sizes of surface-mounted components, the LED display SMT pick and place machineoffers manufacturers the flexibility needed to accommodate diverse product requirements.

- User-friendly Interface: The machine features an intuitive interface that enables operators to easily program, monitor, and control its operations, reducing the learning curve and maximizing productivity.

- Automation Capabilities: The LED display SMT pick and place machine is equipped with advanced automation features, allowing for continuous and unmanned operation, minimizing human errors and downtime.

· Working Principles of LED Display SMT Pick and Place Machine

1. Component Placement:

The LED display SMT pick and place machine utilizes a combination of vision systems, robotic arms, and vacuum nozzles to ensure precise and efficient component placement. The machine first scans the circuit board to identify the correct placement locations for each component. It then uses its automated vision system to align the component with the predefined coordinates on the circuit board. The robotic arms, equipped with the vacuum nozzles, accurately pick up each component from the feeder and place it onto the board.

2. Optimal Soldering Conditions:

After the components are placed on the circuit board, the LED display SMT pick and place machine ensures optimal soldering conditions to create reliable connections. It utilizes various heat control mechanisms, such as hot air and infrared reflow, to achieve precise soldering temperatures. This process guarantees strong and durable bonds between the components and the board, resulting in reliable LED displays.

· Benefits of LED Display SMT Pick and Place Machine

1. Enhanced Efficiency:

The LED display SMT pick and place machine significantly enhances production efficiency by automating the placement process of surface-mounted components. This automation reduces the time and effort required compared to manual assembly, allowing manufacturers to meet tight deadlines and increase production capacity.

2. Improved Accuracy:

With its precise positioning system and automated component placement, the LED display SMT pick and place machine ensures consistently accurate alignment and soldering, minimizing the risk of errors or defective connections. This leads to higher product quality and reliability.

3. Cost Savings:

By streamlining the manufacturing process and reducing human error, the LED display SMT pick and place machine helps manufacturers save costs associated with rework, scrap, and labor expenses. Additionally, the machine's high-speed capabilities enable faster production cycles, resulting in increased output and revenue potential.

LED Display SMT Pick and Place Machine Plays Important Role

The LED display SMT pick and place machine plays a vital role in the manufacturing process of LED displays. With its advanced features, precision, and efficiency, this machine enables manufacturers to meet the demands of the market and deliver high-quality LED displays with speed and accuracy. By embracing this innovative technology, manufacturers can achieve cost savings, improved productivity, and enhanced customer satisfaction in the competitive landscape of LED display production.