이메일 형식 오류

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

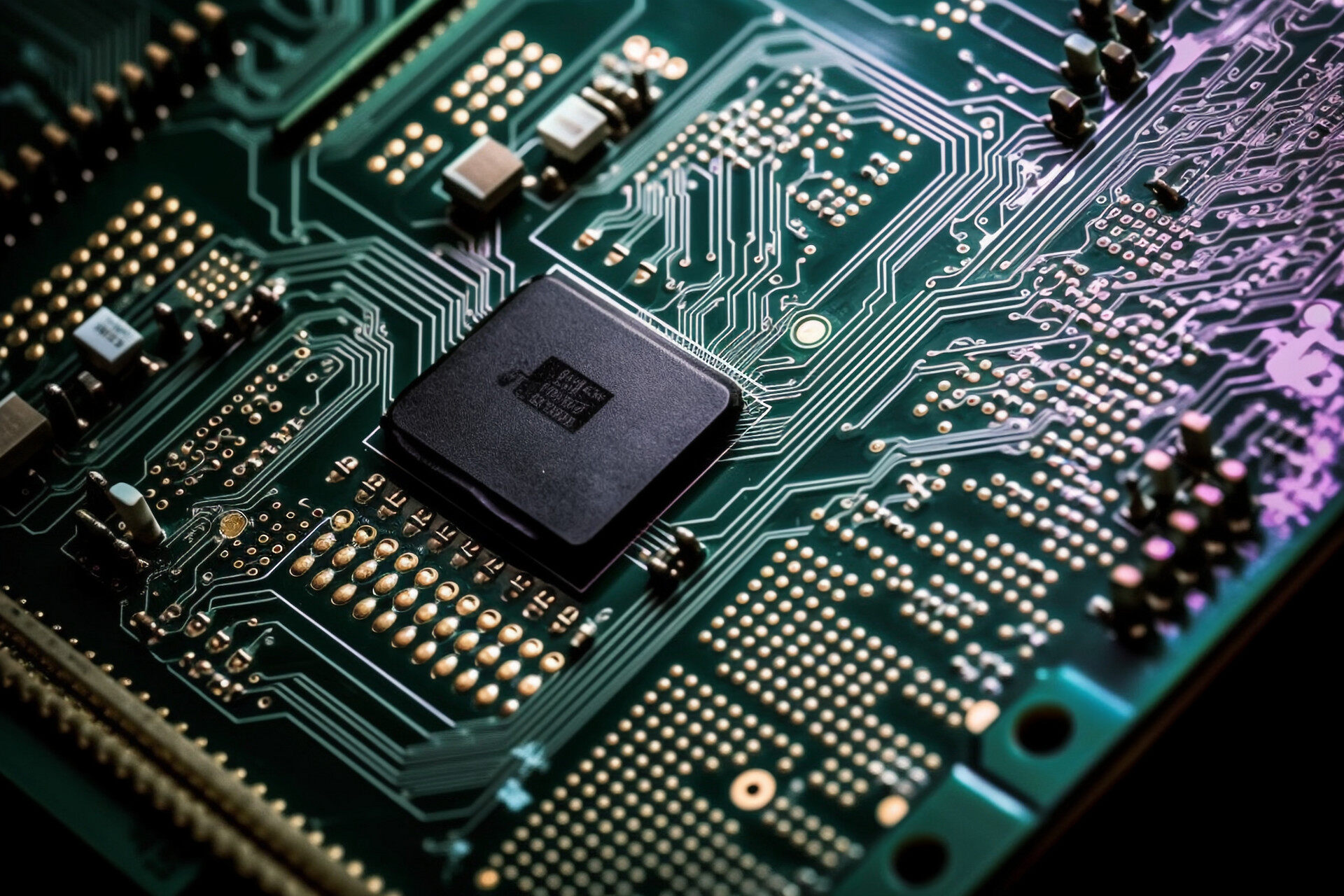

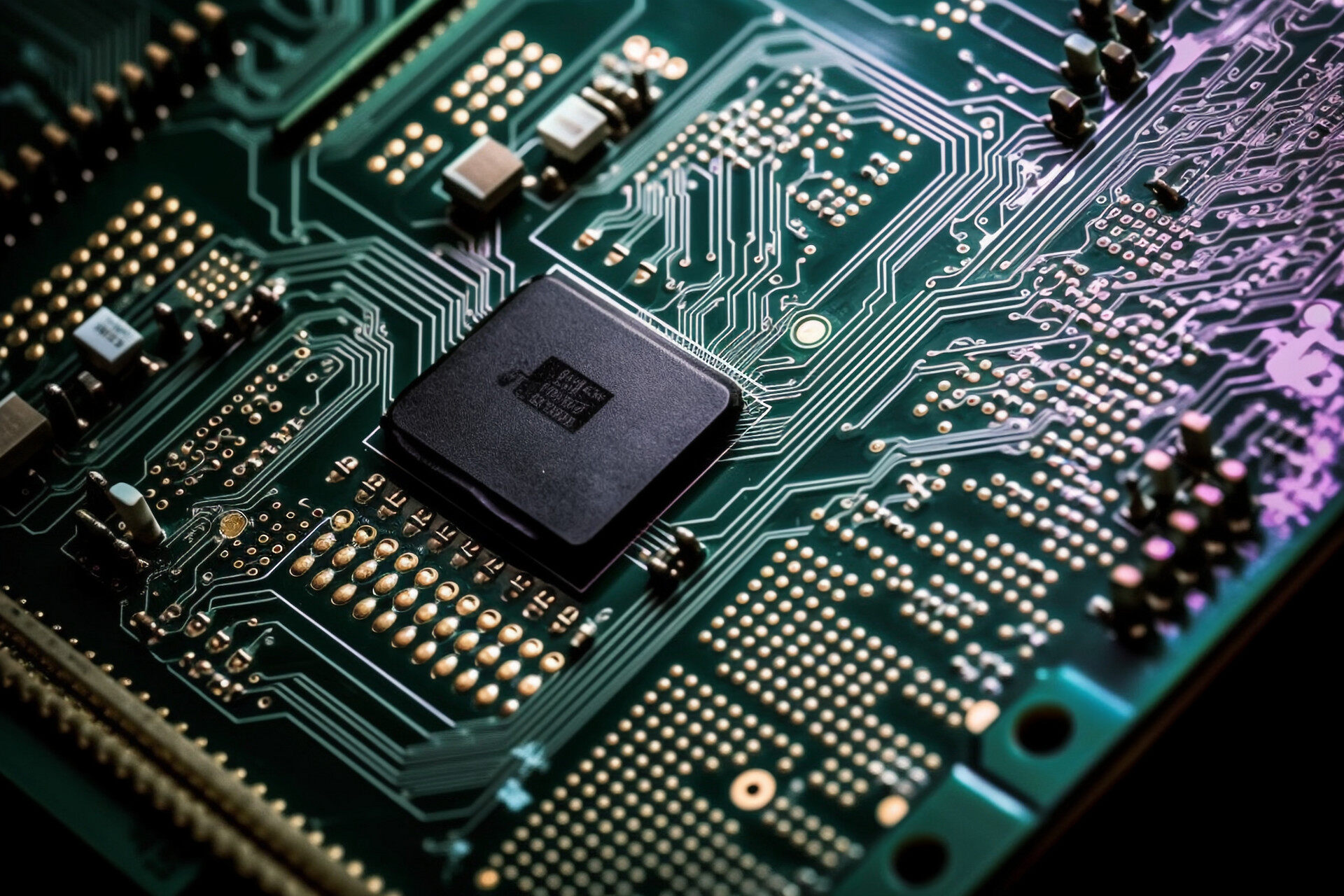

Mastering PCB Assembly with Small Pick and Place Machine for Through-Hole Components

The demand for compact yet efficient solutions is on the rise in today's fast-paced electronics manufacturing landscape. Small pick and place machines designed for through-hole components are revolutionizing PCB assembly processes, offering versatility and precision in a compact footprint. In this comprehensive guide, we'll delve into the world of small pick and place machines for through-hole components, exploring their capabilities, benefits, and practical applications. Whether you're a seasoned professional or a DIY enthusiast, join us as we unlock the potential of these innovative machines.

Section 1: Understanding Small Pick and Place Machines for Through-Hole Components

Unveiling the Basics: Exploring the Fundamentals of Small Pick and Place Machine PCB Thru Hole

In the realm of electronics manufacturing, small pick and place machines for through-hole components represent a fundamental aspect of PCB assembly. These compact yet powerful machines automate the process of picking up electronic components and precisely placing them onto circuit boards, revolutionizing production efficiency. Let's delve into the foundational aspects of these machines to gain a deeper understanding of their operation and significance.

Diving into the Design: Understanding the Key Features and Components of Small Pick and Place Machines

Small pick and place machines for through-hole components boast a design optimized for efficiency and precision. Here, we unravel the key features and components that define these innovative machines:

1. Compact Footprint: Small pick and place machines are characterized by their compact size, making them ideal for space-constrained manufacturing environments. Despite their small footprint, these machines offer impressive capabilities in component handling and placement.

2. High-Speed Performance: Equipped with advanced robotics and motion control systems, small pick and place machines deliver high-speed performance without compromising accuracy. This enables rapid assembly of PCBs with through-hole components, enhancing production throughput and efficiency.

3. Flexible Configuration: Small pick and place machines are designed to accommodate a wide range of through-hole components, including resistors, capacitors, diodes, and connectors. They feature adjustable feeders and nozzles, allowing for seamless integration into diverse assembly workflows.

4. Vision Systems: Many small pick and place machines are equipped with sophisticated vision systems that provide real-time feedback on component alignment and placement. These vision systems ensure precise positioning of components, minimizing errors and rework in PCB assembly.

5. User-Friendly Interface: To streamline operation and programming, small pick and place machines feature intuitive user interfaces that enable operators to program assembly sequences, adjust parameters, and monitor production status with ease. This user-friendly interface enhances productivity and reduces training time for operators.

6. Modular Construction: Small pick and place machines often feature a modular construction that facilitates easy maintenance and upgrades. Components such as feeders, nozzles, and vision systems can be easily replaced or upgraded to adapt to evolving production needs.

7. Integration Capabilities: Small pick and place machines are designed for seamless integration into automated production lines, enabling continuous operation and workflow optimization. They can be integrated with other manufacturing equipment such as soldering stations, inspection systems, and conveyors to create a fully automated assembly process.

Section 2: Benefits of Small Pick and Place Machines for Through-Hole Components

Small pick and place machines for through-hole components offer a plethora of benefits that enhance productivity, optimize space utilization, and ensure precision in component placement. Let's explore these advantages in detail:

Enhanced Efficiency: Maximizing Productivity with Small Pick and Place Machine PCB Thru Hole

Small pick and place machines revolutionize PCB assembly processes by streamlining component placement and increasing production throughput. Here's how they enhance efficiency:

1. Automated Operation: Small pick and place machines automate the tedious and time-consuming task of manually placing through-hole components onto PCBs. By leveraging advanced robotics and motion control systems, these machines can achieve high-speed and accurate component placement, significantly reducing assembly time.

2. Continuous Production: With small pick and place machines, production lines can operate continuously without the need for frequent manual intervention. This continuous operation maximizes productivity and minimizes downtime, leading to higher output and faster time-to-market for electronic products.

3. Optimized Workflow: Small pick and place machines integrate seamlessly into existing production workflows, optimizing assembly processes and minimizing bottlenecks. By eliminating manual handling and assembly errors, these machines ensure consistent quality and reliability in PCB assembly.

4. Reduced Labor Costs: By automating repetitive tasks, small pick and place machines reduce the reliance on manual labor, thereby lowering labor costs and improving overall operational efficiency. This allows manufacturers to allocate resources more effectively and invest in other areas of their business.

Space-Saving Solutions: Harnessing the Compact Design of Small Pick and Place Machines

The compact design of small pick and place machines offers significant space-saving advantages, making them ideal for manufacturing facilities with limited space constraints:

1. Small Footprint: Small pick and place machines occupy minimal floor space compared to traditional assembly equipment, allowing manufacturers to optimize their production layouts and make better use of available space.

2. Modular Configuration: Many small pick and place machines feature a modular design that enables easy customization and integration into existing production lines. This modular configuration ensures maximum flexibility in space utilization and layout planning.

3. Scalability: Small pick and place machines can be scaled up or down to accommodate changing production volumes and requirements. Whether it's a small-scale prototype run or a large-scale production batch, these machines offer scalability without compromising performance or efficiency.

4. Portability: Some small pick and place machines are designed to be portable, allowing manufacturers to move them easily between different workstations or production areas. This portability enhances flexibility and adaptability in dynamic manufacturing environments.

Precision Placement: Achieving Accurate Component Placement with Small Pick and Place Machines

Accurate component placement is critical to the performance and reliability of electronic devices. Small pick and place machines excel in achieving precise placement of through-hole components, offering the following advantages:

1. High Accuracy: Small pick and place machines utilize advanced vision systems and positioning algorithms to achieve sub-millimeter accuracy in component placement. This high level of accuracy ensures consistent and reliable assembly results, minimizing defects and rework.

2. Customizable Placement Parameters: Operators can easily adjust placement parameters such as component orientation, alignment, and spacing to meet specific design requirements. This customization capability allows for precise placement of components on complex PCB layouts.

3. Real-Time Feedback: Small pick and place machines incorporate real-time feedback mechanisms that enable operators to monitor component placement accuracy during the assembly process. Any deviations or errors can be detected and corrected promptly, ensuring optimal assembly quality.

4. Reduced Waste: By placing components with precision and accuracy, small pick and place machines minimize material waste and scrap, resulting in cost savings and improved resource efficiency. This reduction in waste contributes to overall sustainability in manufacturing operations.

Section 3: Practical Applications of Small Pick and Place Machines for Through-Hole Components

Small pick and place machines for through-hole components are versatile tools that find application across various domains of electronics manufacturing. Let's explore some practical applications where these machines excel:

Electronics Prototyping: Accelerating Prototyping Processes with Small Pick and Place Machines

Small pick and place machines play a pivotal role in accelerating the prototyping processes for electronic devices. Here's how:

1. Rapid Iteration: With the ability to quickly pick and place through-hole components onto PCBs, these machines enable engineers and designers to iterate through multiple design revisions rapidly.

2. Design Validation: By automating the assembly of prototype PCBs, small pick and place machines facilitate the validation of circuit designs and component placements, ensuring functionality and performance.

3. Time and Cost Savings: Traditional manual assembly methods for prototyping can be time-consuming and labor-intensive. Small pick and place machines offer significant time and cost savings by automating the assembly process, allowing engineers to focus on design innovation.

4. Customization: Small pick and place machines accommodate a wide range of through-hole components, enabling engineers to prototype custom PCB designs with diverse component requirements.

Low-Volume Production: Optimizing Efficiency in Low-Volume PCB Assembly with Small Pick and Place Machines

Small pick and place machines are ideal for optimizing efficiency in low-volume production scenarios. Here's how they contribute:

1. Flexible Production: In low-volume production runs, traditional high-speed pick and place machines may not be cost-effective. Small pick and place machines offer a flexible alternative, allowing manufacturers to adapt production volumes to match demand fluctuations.

2. Reduced Setup Time: With their user-friendly interfaces and quick setup capabilities, small pick and place machines minimize downtime between production runs, maximizing overall equipment effectiveness (OEE).

3. Streamlined Workflows: By automating the assembly of through-hole components, small pick and place machines streamline production workflows, reducing reliance on manual labor and minimizing the risk of errors.

4. Scalability: Small pick and place machines are scalable solutions that can accommodate growing production volumes. Manufacturers can easily scale up their production capacity by adding additional machines as needed.

Custom PCB Designs: Empowering DIY Enthusiasts with Small Pick and Place Machine Capabilities

Small pick and place machines empower DIY enthusiasts and hobbyists to explore custom PCB designs. Here's how they enable creativity:

1. Accessibility: With the availability of affordable small pick and place machines, DIY enthusiasts can access professional-grade assembly capabilities previously limited to industrial settings.

2. Customization: Small pick and place machines allow DIY enthusiasts to create custom PCB designs tailored to their specific projects and applications, unlocking endless possibilities for innovation.

3. Learning Opportunities: By experimenting with small pick and place machines, DIY enthusiasts gain valuable hands-on experience in PCB assembly, electronics prototyping, and automation technologies.

4. Community Engagement: Small pick and place machines foster collaboration and knowledge sharing within DIY communities, providing a platform for enthusiasts to exchange ideas, designs, and best practices.

Section 4: Choosing the Right Small Pick and Place Machine for Your Needs

In the realm of electronics manufacturing, selecting the right small pick and place machine for your specific needs is crucial for achieving optimal production efficiency and quality. This section will guide you through the key considerations and comparative analysis necessary for making an informed decision.

Key Considerations: Factors to Evaluate When Selecting a Small Pick and Place Machine PCB Thru Hole

When evaluating small pick and place machines, it's essential to consider several key factors to ensure compatibility with your production requirements and workflow. Here are the critical considerations:

1. Through-Hole Component Compatibility: Ensure that the machine supports the range of through-hole components required for your applications, including component sizes, shapes, and lead configurations.

2. Production Volume: Assess your production volume requirements to determine whether the machine can meet your throughput targets efficiently. Consider factors such as cycle time, feeder capacity, and placement speed.

3. Accuracy and Precision: Evaluate the machine's placement accuracy and precision, as well as its ability to handle fine-pitch components and achieve consistent placement results across various PCB designs.

4. Ease of Use and Programming: Look for a machine with an intuitive user interface and easy-to-use programming software that streamlines setup, operation, and programming tasks. This ensures minimal training requirements for operators and reduces setup time between production runs.

5. Flexibility and Versatility: Consider the machine's flexibility in accommodating diverse PCB designs, component types, and production requirements. Look for features such as adjustable feeder positions, nozzle configurations, and vision system capabilities.

6. Footprint and Space Requirements: Evaluate the machine's physical footprint and space requirements to ensure compatibility with your facility layout and production environment. Consider factors such as machine dimensions, access for maintenance, and clearance space for operator safety.

7. Maintenance and Support: Assess the availability of technical support, training resources, and spare parts for the machine. Choose a manufacturer or supplier with a reputation for responsive customer service and comprehensive maintenance programs.

8. Cost and Return on Investment (ROI): Consider the initial investment cost of the machine, as well as ongoing operational expenses such as maintenance, consumables, and operator labor. Evaluate the machine's ROI based on its capabilities, productivity gains, and long-term reliability.

Comparative Analysis: Exploring Different Models and Brands of Small Pick and Place Machines

Conducting a comparative analysis of different models and brands of small pick and place machines allows you to assess their features, capabilities, and performance against your specific requirements. Here's a framework for conducting a comparative analysis:

1. Feature Comparison: Compare the key features and specifications of different small pick and place machines, including placement accuracy, speed, feeder capacity, vision system capabilities, and software functionality.

2. Performance Evaluation: Evaluate the performance of each machine through demonstrations, trials, or user reviews. Assess factors such as placement accuracy, reliability, ease of setup, and overall productivity.

3. User Feedback and Reviews: Seek feedback from current users or industry experts who have experience with the machines you're considering. User reviews and testimonials can provide valuable insights into real-world performance and reliability.

4. Cost-Benefit Analysis: Compare the upfront costs, ongoing expenses, and potential ROI of each machine to determine the best value proposition for your investment. Consider factors such as total cost of ownership, productivity gains, and long-term reliability.

5. Manufacturer Reputation: Research the reputation and track record of each machine's manufacturer or supplier. Choose a reputable company with a history of delivering high-quality products, responsive customer support, and reliable after-sales service.

Section 5: Setting Up and Operating a Small Pick and Place Machine for Through-Hole Components

Small pick and place machines for through-hole components offer remarkable capabilities in PCB assembly, but proper setup and operation are essential to unlock their full potential. In this section, we'll provide a comprehensive guide to setting up your machine for optimal performance and share valuable tips and tricks for maximizing efficiency and accuracy during PCB assembly.

Step-by-Step Guide: Setting Up Your Small Pick and Place Machine for Optimal Performance

Setting up your small pick and place machine requires careful attention to detail to ensure smooth operation and accurate component placement. Follow these steps for a successful setup:

1. Prepare the Workspace: Clear the workspace of any debris or obstructions and ensure adequate lighting for optimal visibility during setup.

2. Machine Installation: Follow the manufacturer's instructions to install the small pick and place machine securely on a stable surface, ensuring proper alignment and stability.

3. Power and Connectivity: Connect the machine to a reliable power source and ensure all necessary cables and connections are properly secured.

4. Feeder and Nozzle Setup: Install and configure the feeders and nozzles according to the component specifications and placement requirements. Ensure proper alignment and calibration for accurate component pickup.

5. Vision System Calibration: Calibrate the vision system to ensure accurate component recognition and placement. Adjust camera angles, lighting conditions, and image processing parameters as needed for optimal performance.

6. Software Configuration: Install and configure the machine's software interface, inputting PCB design files and programming assembly sequences as required. Familiarize yourself with the software's features and functionality to streamline operation.

7. Testing and Validation: Conduct thorough testing and validation procedures to ensure the machine operates smoothly and accurately. Run test placements on sample PCBs and verify component alignment and placement accuracy.

8. Documentation and Training: Document the setup process and create comprehensive operating procedures for reference. Provide training to operators on machine operation, maintenance, and troubleshooting protocols.

By following these steps, you can set up your small pick and place machine with confidence, laying the groundwork for efficient and accurate PCB assembly.

Operating Tips and Tricks: Maximizing Efficiency and Accuracy During PCB Assembly

Operating a small pick and place machine requires skill and attention to detail to achieve optimal efficiency and accuracy. Consider the following tips and tricks:

1. Optimize Component Placement: Arrange components on feeders strategically to minimize travel distances and optimize placement speed. Group components with similar characteristics to streamline assembly sequences.

2. Monitor Production Parameters: Regularly monitor production parameters such as placement speed, accuracy, and feed rates to identify any anomalies or deviations from expected performance.

3. Perform Regular Maintenance: Implement a proactive maintenance schedule to keep the machine running smoothly and prevent downtime due to mechanical failures or component wear. Clean feeders, nozzles, and vision systems regularly to ensure optimal performance.

4. Fine-Tune Machine Settings: Experiment with machine settings such as nozzle heights, placement pressures, and vision system thresholds to optimize performance for specific components or PCB designs.

5. Troubleshooting Protocols: Develop standardized troubleshooting protocols to quickly diagnose and resolve common issues such as component misplacements, feeder jams, or vision system errors. Train operators on these protocols to minimize production disruptions.

6. Continuous Improvement: Regularly review production data and performance metrics to identify areas for improvement and implement process optimizations. Encourage feedback from operators and incorporate their insights into refining assembly workflows.

Section 6: Maintenance and Troubleshooting for Small Pick and Place Machines

Small pick and place machines for through-hole components are precision instruments that require regular maintenance to ensure optimal performance. Additionally, being familiar with troubleshooting techniques can help address common issues swiftly, minimizing downtime. In this section, we'll explore both routine maintenance practices and troubleshooting strategies to keep your small pick and place machine running smoothly.

Routine Maintenance: Implementing Best Practices to Keep Your Small Pick and Place Machine Running Smoothly

Effective routine maintenance is essential for maximizing the lifespan and performance of your small pick and place machine. Here's a guide to implementing best practices:

1. Regular Cleaning: Dust, debris, and solder flux residues can accumulate on the machine's components over time, affecting performance. Clean the machine thoroughly using appropriate tools and solvents as per the manufacturer's recommendations.

2. Lubrication: Lubricate moving parts such as linear guides and drive mechanisms regularly to minimize friction and wear. Use lubricants recommended by the manufacturer to ensure compatibility and effectiveness.

3. Component Inspection: Periodically inspect components such as feeders, nozzles, and vision systems for signs of wear, damage, or misalignment. Replace any worn or damaged components promptly to prevent issues during operation.

4. Software Updates: Keep the machine's software up to date by installing the latest updates and patches provided by the manufacturer. Updated software may include bug fixes, performance enhancements, and new features.

5. Calibration: Regularly calibrate the machine's vision system to maintain accurate component placement. Follow the calibration procedures outlined in the machine's user manual and perform adjustments as necessary.

6. Documentation: Maintain detailed records of maintenance activities, including cleaning schedules, lubrication intervals, and component replacements. This documentation helps track machine performance over time and identify any recurring issues.

Troubleshooting Guide: Identifying and Resolving Common Issues with Small Pick and Place Machines

Despite meticulous maintenance, small pick and place machines may encounter occasional issues during operation. Here's a troubleshooting guide to help you identify and resolve common problems:

1. Component Misfeeds: If components are not feeding properly into the machine, check for obstructions or misalignments in the feeder mechanisms. Clean the feeders and adjust their settings as needed to ensure smooth component feeding.

2. Placement Errors: Inaccurate component placement can occur due to issues with the vision system or mechanical components. Inspect the vision system for dirt or damage and recalibrate if necessary. Check for worn or misaligned nozzles and replace them if needed.

3. Machine Jams: If the machine becomes jammed during operation, power off the machine immediately and inspect the affected area for obstructions. Clear any debris or jammed components carefully to prevent damage to the machine.

4. Software Glitches: If the machine's software malfunctions or freezes, restart the machine and check for any error messages or warning lights. If the issue persists, contact the manufacturer's technical support team for assistance.

5. Motor or Drive Failures: If the machine's motors or drive mechanisms fail to operate properly, check for loose connections or damaged components. Consult the machine's user manual for troubleshooting steps specific to the motor or drive system.

Section 7: Future Trends and Innovations in Small Pick and Place Machine Technology

In the rapidly evolving landscape of electronics manufacturing, small pick and place machines for through-hole components continue to undergo innovative advancements. This section delves into the latest emerging technologies and industry outlook, shedding light on the future trajectory of these indispensable machines.

Emerging Technologies: Exploring the Latest Advancements in Small Pick and Place Machine PCB Thru Hole

1. Advanced Vision Systems: Future small pick and place machines are expected to feature enhanced vision systems equipped with artificial intelligence and machine learning algorithms. These systems will offer improved component recognition and placement accuracy, minimizing errors and optimizing production efficiency.

2. Collaborative Robotics: Collaborative robots, or cobots, are poised to revolutionize the field of electronics assembly. Future small pick and place machines may integrate collaborative robotics technology to enable seamless interaction between human operators and automated assembly processes, enhancing flexibility and productivity.

3. IoT Integration: Internet of Things (IoT) connectivity is becoming increasingly prevalent in manufacturing equipment, including small pick and place machines. IoT-enabled machines will provide real-time monitoring and remote diagnostics capabilities, allowing manufacturers to optimize performance and troubleshoot issues more effectively.

4. 3D Printing Integration: The integration of 3D printing technology into small pick and place machines holds the potential to expand their capabilities beyond traditional PCB assembly. Future machines may incorporate 3D printing modules for on-demand fabrication of custom fixtures, tooling, and enclosures, streamlining production workflows and reducing lead times.

5. Modular Design: Future small pick and place machines are likely to feature modular designs that facilitate easy customization and scalability. Manufacturers will be able to configure machines according to specific production requirements and upgrade them with additional modules as needed, ensuring adaptability to evolving manufacturing needs.

Industry Outlook: Predicting the Future of Small Pick and Place Machines and Their Impact on Electronics Manufacturing

1. Increased Automation: As automation continues to gain traction in electronics manufacturing, small pick and place machines will play a central role in driving efficiency and productivity. Manufacturers will increasingly rely on these machines to automate labor-intensive assembly processes, resulting in higher throughput and lower production costs.

2. Greater Customization: With advancements in technology and modular design, small pick and place machines will offer greater flexibility and customization options. Manufacturers will be able to tailor machines to their specific application requirements, whether it's prototyping, low-volume production, or high-mix, low-volume manufacturing.

3. Integration with Industry 4.0: Small pick and place machines will be integral components of Industry 4.0 initiatives, facilitating seamless connectivity and data exchange within smart factories. These machines will leverage data analytics, artificial intelligence, and predictive maintenance algorithms to optimize production processes and drive continuous improvement.

4. Ecosystem Collaboration: Collaboration between small pick and place machine manufacturers, software developers, and component suppliers will foster innovation and interoperability within the electronics manufacturing ecosystem. Integrated solutions that combine machine automation, intelligent software, and quality components will empower manufacturers to achieve higher levels of efficiency and competitiveness.

5. Sustainability Focus: In response to growing environmental concerns, future small pick and place machines will prioritize sustainability by incorporating energy-efficient technologies, recyclable materials, and eco-friendly manufacturing practices. Manufacturers will seek to minimize waste and carbon footprint while maximizing resource utilization and operational efficiency.

Conclusion: Embracing the Future of PCB Assembly with Small Pick and Place Machines

As we journey through the realm of electronics manufacturing, one thing remains abundantly clear: small pick and place machines for through-hole components are poised to lead the charge into the future of PCB assembly. In this conclusion, let's reflect on the innovative solutions offered by these machines and the boundless potential they hold for enhancing productivity and precision in electronics manufacturing.

Unlocking the Potential: Small pick and place machines represent the epitome of innovation, offering a blend of compact design, high-speed performance, and precision placement capabilities. By harnessing the power of automation and advanced technologies, these machines unlock new levels of productivity and efficiency in PCB assembly processes.

Enhanced Productivity: With their rapid assembly speeds and seamless integration into manufacturing workflows, small pick and place machines revolutionize production processes, enabling manufacturers to meet growing demand with ease. By automating labor-intensive tasks and minimizing human error, these machines maximize throughput and minimize production costs, ultimately driving greater profitability and competitiveness.

Precision and Accuracy: At the heart of small pick and place machines lies a commitment to precision and accuracy in component placement. Equipped with advanced vision systems, intelligent algorithms, and meticulous calibration, these machines ensure consistent and reliable assembly results, meeting the highest quality standards in electronics manufacturing.

Adaptability and Flexibility: In an ever-changing manufacturing landscape, adaptability is key to success. Small pick and place machines offer unparalleled flexibility, allowing manufacturers to customize production processes according to specific requirements and adapt to evolving market demands. Whether it's prototyping, low-volume production, or high-mix, low-volume manufacturing, these machines rise to the challenge with versatility and efficiency.

Continued Innovation: As we look to the future, the journey of innovation in small pick and place machine technology shows no signs of slowing down. Emerging technologies such as advanced vision systems, collaborative robotics, and IoT integration will further enhance the capabilities of these machines, opening up new possibilities for electronics manufacturing.

In conclusion, small pick and place machines for through-hole components stand at the forefront of PCB assembly, offering innovative solutions that unlock the full potential of electronics manufacturing. By embracing these machines and the future of automation, we embark on a journey toward enhanced productivity, precision, and profitability. Let us continue to innovate, collaborate, and push the boundaries of what is possible, as we shape the future of PCB assembly together.