이메일 형식 오류

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Understanding the China Hot Air Reflow Soldering Machine: A Comprehensive Guide

The manufacturing industry relies heavily on efficient soldering methods to ensure the production of high-quality electronic components. Among these methods, the China hot air reflow soldering machine stands out as a critical piece of equipment. In this blog, we will delve into the specifics of this machine, its benefits, applications, and why it is a preferred choice for many electronics manufacturers around the globe.

What is a China Hot Air Reflow Soldering Machine?

A China hot air reflow soldering machine is an advanced piece of equipment used in the electronics manufacturing process. It employs hot air to melt solder paste applied to the joints of electronic components on a printed circuit board (PCB). The reflow process involves heating the entire assembly to a temperature sufficient to melt the solder, allowing it to flow and form reliable electrical connections.

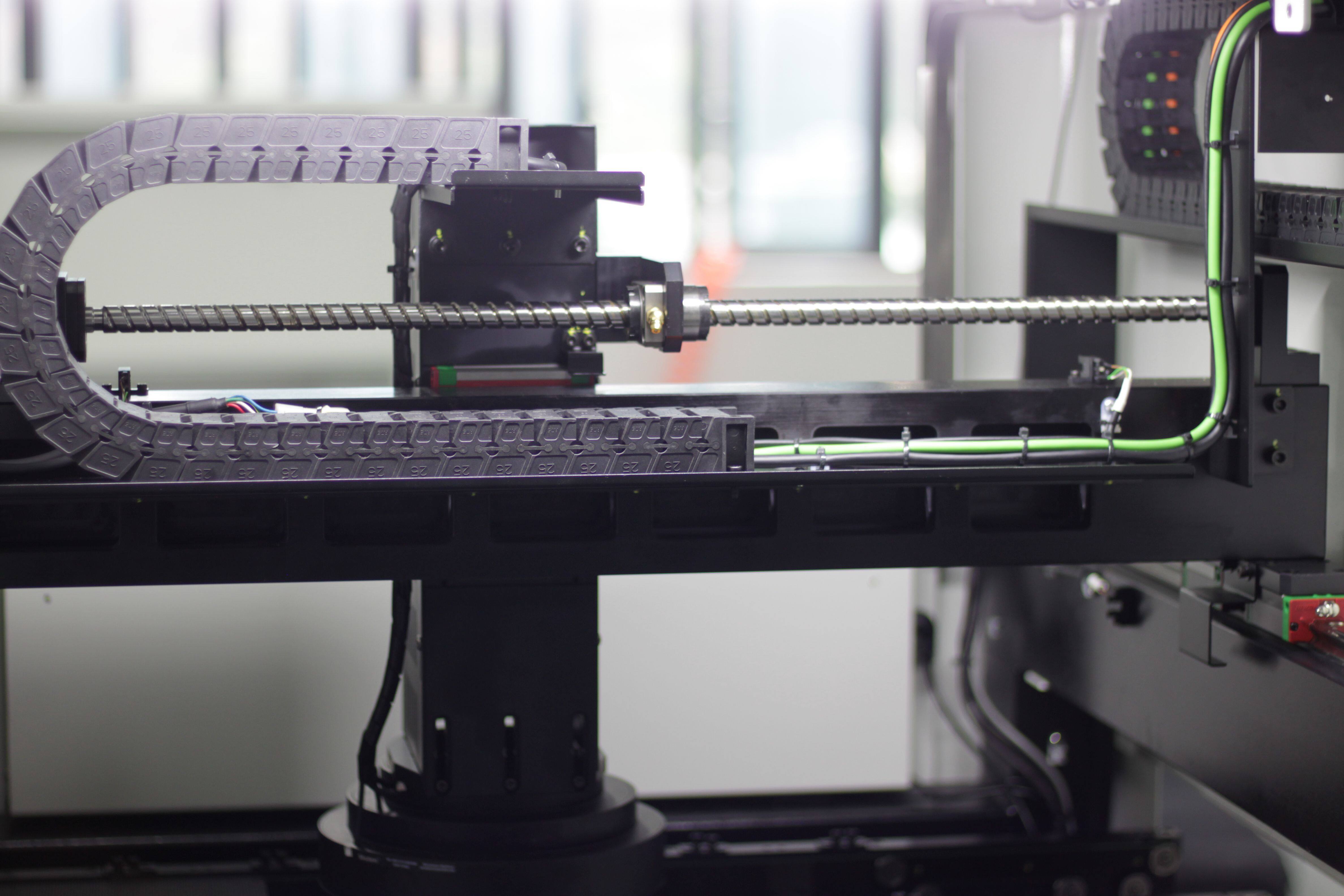

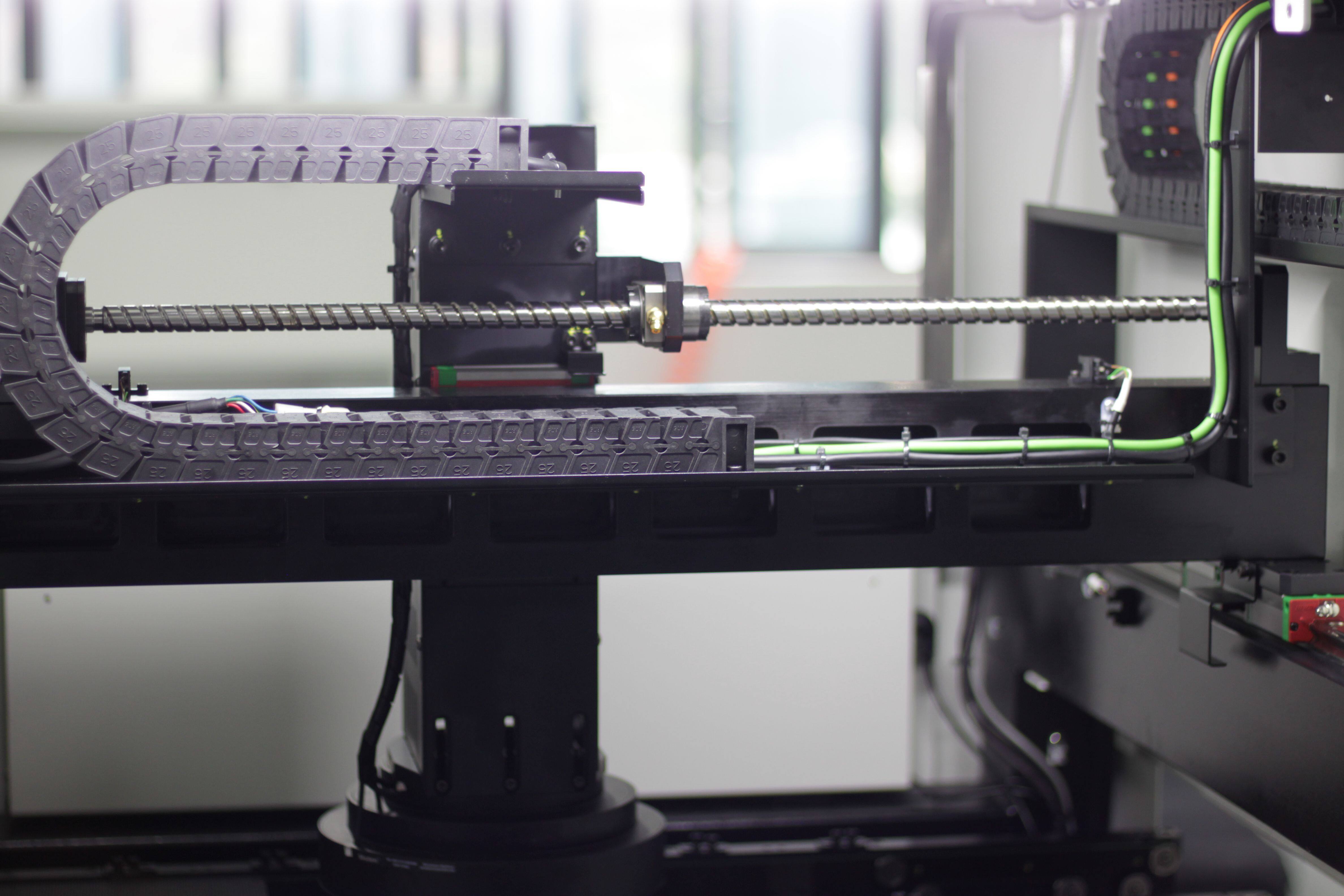

Components of a Hot Air Reflow Soldering Machine

1. Preheat Zone: This is where the PCB is gradually heated to prevent thermal shock.

2. Soak Zone: In this zone, the PCB and components are maintained at a uniform temperature to activate the flux and remove oxidation.

3. Reflow Zone: The temperature is raised above the melting point of the solder, causing it to reflow.

4. Cooling Zone: The assembly is gradually cooled to solidify the solder joints and complete the process.

The Importance of Hot Air Reflow Soldering

The China hot air reflow soldering machine plays a crucial role in modern electronics manufacturing for several reasons:

- Precision and Consistency: It ensures precise temperature control and uniform heating, resulting in consistent solder joints.

- Efficiency: It allows for high-volume production with minimal manual intervention.

- Quality: The process reduces the risk of defects such as cold joints and voids, ensuring reliable electronic assemblies.

Key Benefits of Using a China Hot Air Reflow Soldering Machine

1. Cost-Effectiveness

One of the primary advantages is cost-effectiveness. These machines are often more affordable than their counterparts from other regions, making them an attractive option for small to medium-sized enterprises.

2. Advanced Technology

Chinese manufacturers have integrated advanced technologies into their hot air reflow soldering machines. Features such as real-time temperature monitoring, automated conveyor systems, and programmable profiles enhance the machine's efficiency and reliability.

3. Energy Efficiency

Modern hot air reflow soldering machines are designed with energy efficiency in mind. They consume less power while maintaining optimal performance, contributing to lower operational costs and a reduced environmental footprint.

4. Customizability

Chinese manufacturers offer a high degree of customizability for their reflow soldering machines. Customers can specify requirements such as conveyor speed, heating zones, and cooling systems to tailor the machine to their specific production needs.

Applications of China Hot Air Reflow Soldering Machines

The versatility makes it suitable for a wide range of applications in the electronics industry. Some of the common uses include:

1. PCB Assembly

Reflow soldering is a critical step in the PCB assembly process. It ensures secure connections between components and the board, which is essential for the functionality of electronic devices.

2. Surface-Mount Technology (SMT)

In SMT, components are placed directly onto the surface of PCBs. The reflow soldering process is used to attach these components, ensuring strong and reliable bonds.

3. LED Manufacturing

LEDs are used in a variety of applications, from consumer electronics to automotive lighting. The China hot air reflow soldering machine is instrumental in the production of LED circuits, ensuring consistent quality and performance.

4. Consumer Electronics

From smartphones to laptops, the reliability of consumer electronics depends on the quality of the solder joints. Reflow soldering ensures that these devices perform reliably over their lifespan.

Choosing the Right China Hot Air Reflow Soldering Machine

Selecting the right China hot air reflow soldering machine for your manufacturing needs involves considering several factors:

1. Throughput Requirements

Determine the volume of production you need to meet. High-volume production lines may require machines with faster conveyor speeds and larger processing capacities.

2. PCB Size and Complexity

Consider the size and complexity of the PCBs you will be working with. Ensure the machine can accommodate the largest board size you plan to process.

3. Heating Zones

Machines with multiple heating zones allow for more precise temperature control and are suitable for complex assemblies with varying thermal requirements.

4. Budget

While cost is a significant factor, it’s essential to balance affordability with the features and capabilities needed to meet your production goals.

Maintenance and Troubleshooting

Proper maintenance of your China hot air reflow soldering machine is essential to ensure its longevity and optimal performance. Here are some maintenance tips:

1. Regular Cleaning

Keep the machine clean to prevent the buildup of flux residues, which can affect performance and lead to defects.

2. Calibration

Regularly calibrate temperature sensors and conveyor systems to ensure accurate and consistent operation.

3. Inspection

Inspect the machine regularly for signs of wear and tear. Replace worn-out parts promptly to prevent breakdowns and ensure continuous operation.

4. Software Updates

Stay updated with the latest software upgrades from the manufacturer. These updates can enhance the machine’s functionality and efficiency.

Future Trends in Reflow Soldering Technology

The China hot air reflow soldering machine industry is continuously evolving, with new trends and technologies emerging. Here are some future trends to watch:

1. IoT Integration

The integration of the Internet of Things (IoT) in reflow soldering machines allows for real-time monitoring and data analysis, improving process control and predictive maintenance.

2. Automation

Increased automation in reflow soldering processes reduces the need for manual intervention, enhancing efficiency and reducing the risk of human error.

3. Environmental Sustainability

As environmental concerns grow, manufacturers are focusing on developing reflow soldering machines that are more energy-efficient and use environmentally friendly materials.

4. Advanced Materials

The use of advanced materials, such as lead-free solder and high-performance fluxes, is becoming more common, driven by regulatory requirements and the need for higher performance.

Conclusion

The China hot air reflow soldering machine is a pivotal tool in the electronics manufacturing industry. Its ability to provide precise, consistent, and efficient soldering makes it an invaluable asset. By understanding its components, benefits, applications, and maintenance requirements, manufacturers can make informed decisions that enhance their production capabilities and ensure high-quality outputs.

As technology continues to advance, the future of reflow soldering looks promising, with innovations that will further streamline the manufacturing process and contribute to the production of reliable and sophisticated electronic devices.