이메일 형식 오류

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

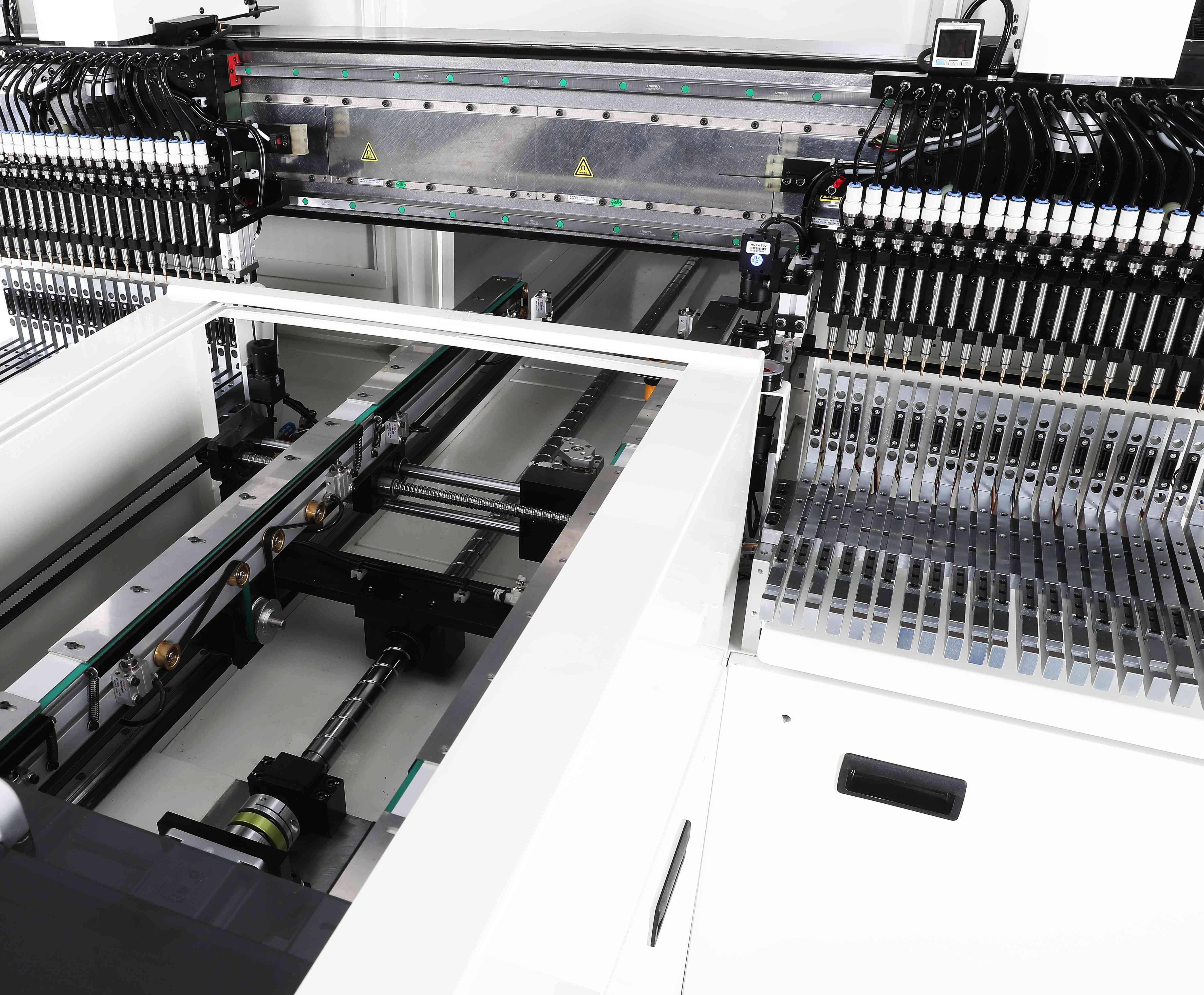

HCT-830L High-speed LED Chip Mounter

With the development of science and technology, electronic items are a part of everyone's life. To fulfill its purpose, every electrical product needs a PCB as a carrier. Some PCBs contain hundreds of components, and manual soldering of PCBs has long fallen short of market demands. The PCB component placement machine is the most crucial piece of the PCB assembly chain, and the simplest SMT line typically comprises a solder printer, a pick and place device, and a reflow oven.

Technical Parameters - High-Speed LED Chips Mounter HCT-830L

|

Model |

HCT-830L |

||

|

Vision System |

5 Sets of Camera, Mark Correction |

||

|

Number of Spindles |

18 Spindles x2 Gantry |

||

|

RatedPlacement Speed |

LED 2835 170,000 CPH (Group Picking & Group Placing) |

||

|

Placement Accuracy |

±0.05mm (Based on the standard chips) |

||

|

Component Range |

Standard |

LED3014, 3020, 3528, 2835, 5730, 5630, 5050, 7030and Resistor 0805, 1206 |

|

|

Max Height |

H=8mm |

||

|

Board Dimension(mm) |

Maximum |

1,200(L) x 330(W) |

|

|

PCB Thickness |

0.5 - 3.0 |

||

|

Tape Feeder |

Feeder Type |

Electric Feeder |

|

|

Feeder Capacity |

72 (12mm) |

||

|

Optional |

8mm, 12mm, 16mm, 24mm |

||

|

Utility |

Power |

AC 220V/240V 50/60Hz, Single phase |

|

|

Max2.6KW |

|||

|

Air Consumption |

0.55-0.7MPa (5.6-7.1kgf/cm2) |

||

|

Mass |

Approx. 1500kg |

||

|

External Dimension(mm) |

2,350(L) x2,450(D) x 1,425(H) |

||

Product Features - High-Speed LED Chips Mounter HCT-830L

1. Dual mounting arm design, 36 placement heads available. Can put 4 sets of feeders, a total of 72 feeders, components reloading doesn’t affect the production capacity.

2. High-speed: Maximum placement speed reaching 0.027s/chip.

With a SMEMA-compatible inline conveyor for line automation. Complete intelligent production, save labor, and greatly improve efficiency and production capacity.

3. Placement Range: 4 kinds of RGB components can be handled at the same time, suitable for LED T5/T8, LED panel light, LED strip, diffuse reflection, and LED outdoor screen of 1.2m long or less.

4. Magnetic levitation linear motor for high repeatability and stability.

PCB Clamping Mode: automatic width adjustment for conveyor rail, floating clamping, improve efficiency and portability.

5. Excellent quality hardware support by using international famous brands ensures placement repeatability and precision.

6. Self-developed software simplifies production, easy to operate, and programming.

With the advancement of science and technology, everyone is inseparable from electronic products. Every electronic product needs PCB as a carrier to realize its function. There are hundreds of components on some PCBs, and manual soldering of PCBs has long been unable to meet the needs of the market. Generally, the simplest SMT line requires a solder printer, a pick and place machine, and a reflow oven, and the PCB component placement machine is the most important link in PCB assembly.

Product Display - High-Speed LED Chips Mounter HCT-830L