이메일 형식 오류

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

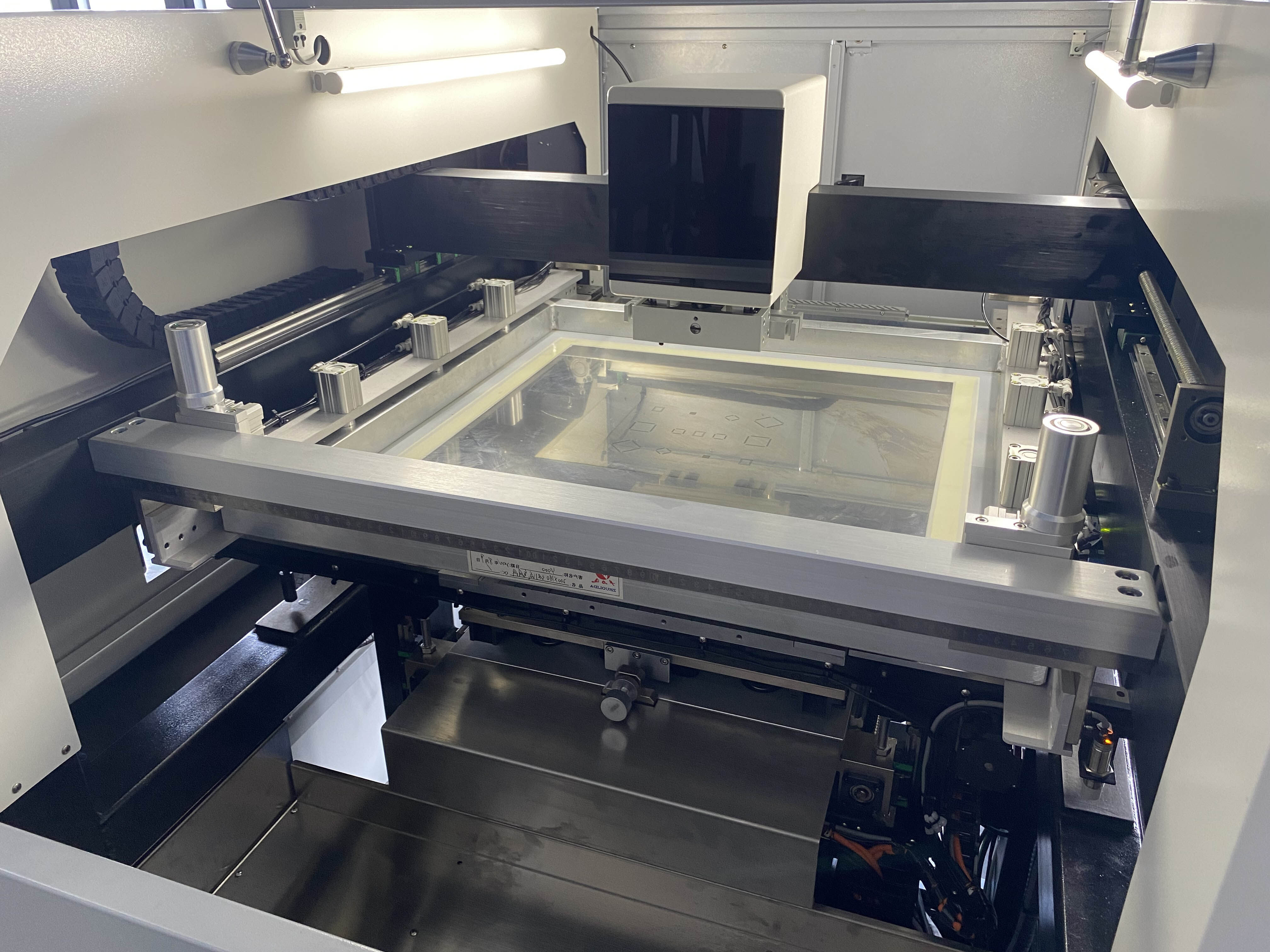

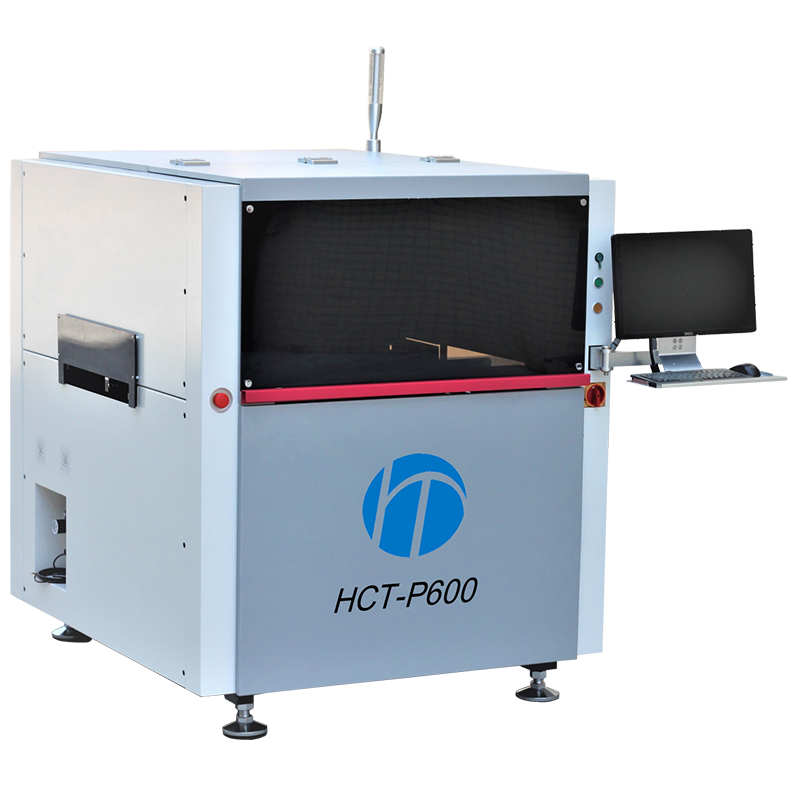

High Accuracy Automatic Solder Paste Stencil Printer

The system offers three different cleaning techniques—dry cleaning, wet cleaning, and vacuum—that can be combined in any way and support manual cleaning in the production interface, cutting down on cleaning time and boosting production effectiveness.

Solder Paste Stencil Printer Machine

A solder paste stencil printer machine is a device used in the electronics manufacturing industry to apply solder paste onto printed circuit boards (PCBs) with high precision. Here's some information about solder paste stencil printers:

What is a solder paste stencil?

- A solder paste stencil is a thin metal or plastic sheet with precise cutouts that match the locations of the solder pads on a PCB.

- The stencil acts as a guide for applying solder paste only to the desired areas, ensuring accurate placement of solder during the subsequent assembly process.

How does a solder paste stencil printer work?

- Setup: The operator places the solder paste stencil onto the printer's base, aligning it with the PCB.

- Alignment: The printer uses vision systems or fiducial markers on the PCB to precisely align the stencil with the board's solder pads.

- Solder paste deposition: The printer applies solder paste onto the stencil.

- Printing: The printer uses a squeegee or a similar mechanism to push the solder paste through the stencil's apertures and onto the PCB's solder pads.

- Inspection: After printing, the PCB is usually inspected to ensure the quality of the solder paste application.

Advantages of using a solder paste stencil printer:

- Precision: Stencil printers offer high accuracy and repeatability, ensuring consistent results.

- Time-saving: They automate the solder paste application process, reducing manual labor and increasing productivity.

- Cost-effective: By preventing excessive use of solder paste, these machines help minimize material waste.

Considerations when using a solder paste stencil printer:

- Design compatibility: The stencil must be properly designed to match the PCB layout for accurate solder paste deposition.

- Stencil cleaning: Stencils should be cleaned regularly to remove excess solder paste or contaminants that could affect future prints.

- Maintenance: Regular maintenance and calibration of the printer are necessary to keep it in optimal working condition.

Solder paste stencil printers play a crucial role in the surface mount technology (SMT) assembly process, enabling precise and efficient solder paste deposition on PCBs.

Technical Parameters - High Accuracy Automatic Stencil Printer

|

PCB Handling Parameter |

|

|

Max. Board Size(X x Y) |

600x 350mm |

|

Min. Board Size(X x Y) |

50mm x 50mm |

|

PCB Thickness Range: |

0.4mm~6mm |

|

PCB Warpage |

≤1% Diagonal |

|

Max. Board Weight |

3Kg |

|

PCB Edge Clearance |

3mm |

|

PCB Bottom Clearance |

20mm |

|

Conveyor Speed (Max.) |

1subdivision control,500mm/s(Max) |

|

Conveyor Height |

900±40mm |

|

Conveyor Direction |

L-R, R-L, L-L, R-R |

|

Transfer Mode |

One Stage Conveyor |

|

PCB Clamping Method |

Side flexible clamping; Top pressing leveling; Bottom integral suction cavity vacuum/multi-point local vacuum |

|

Support Method |

Magnetic thimble + Equal high block.(Optional:1.vacuum suction cavity;2.special work-piece fixture) |

|

Printing Parameters |

|

|

Print Head |

IndependentLevitatingIntelligentPrintingHead |

|

Stencil Frame Size |

370mm x 400mm~800 mm x 800 mm: Thickness20mm~40mm |

|

Max. Printing Area(X x Y) |

600mm x 350mm |

|

Squeegee Material/Angle |

Steel squeegee/ Rubber squeegee (Angel 45°/50°/60° matching the printing process) |

|

Print Mode |

Single or dual squeegee printing |

|

DemouldingLength |

0 mm - 6 mm |

|

Print Speed |

0 ~ 200 mm/s |

|

Print Pressure |

0.5kg - 10Kg |

|

SqueegeeStroke |

±180 mm(From the center) |

|

Cleaning Parameters |

|

|

Cleaning System |

1. Programmable washer fluid injection system; 2. Dry, wet and vacuum modes |

|

CleaningSystemLocation |

At the back of the machine |

|

Optical System |

|

|

Field of View |

10mm x 8mm |

|

Printing Table Adjustment Range |

X:±20.0mm,Y:±20.0mm,θ:±2.0° |

|

Fiducial Types |

Standard Fiducial type or custom image(SMEMA standard), solder pad/openings |

|

Vision Methodology |

Independent camera,upwards/downwards imaging vision system, geometric matching location |

|

Performance Parameters |

|

|

Machine Alignment Repeatability |

±10.0μm @6 σ,Cpk ≥ 2.0 |

|

Full Process Repeatability |

±15.0μm @6 σ,Cpk ≥ 2.0 |

|

Core Cycle Time |

7.5s (Exclude printing and cleaning) |

|

Product Changeover Time |

<5min |

|

Equipment |

|

|

Power |

AC220V±10%,50/60HZ,2.5KW |

|

Air Supply |

Air tube¢10mm,4~6Kg/cm² |

|

Air Consumption |

About 5L/min |

|

Operating System (OS) |

Windows 7 |

|

External Dimension |

(L)1150mm x (W)1450mm x(H)1500mm (Without light,monitor and keyboard) |

|

Machine Weight |

Appro.1000Kg |

|

Environment Request |

Temperature - 20 ~ + 40; Humidity 30% ~ 60% |

Product Features - High Accuracy Automatic Stencil Printer

1. platform agency

The HCT-P600 has a high-rigidity platform mounted on a sturdy base. High strength and low vibration characteristics provide long-term high repeatability and high reliability.

2. Calibration technology

To deal with the problem of substrate expansion and contraction, the HCT-P600 printer determines the offset compensation scheme for substrate printing by reading the position data of the substrate Mark and Stencil Mark and using a unique calibration algorithm for comparative analysis. Through this method, the substrate can present the best printability, fully release the quality and process performance of the machine, and save costs for customers.

3. Image and optical system

Using a special light source with a large field of view and a telecentric lens, all types of Mark points can be well identified (including uneven Mark points), suitable for tin plating, copper plating, gold plating, tin spraying, FPC, and other types of different color PCB;

4. Programmable suspended self-adjusting stepper motor to drive the print head

It is designed for the difference in the pressure of the front and rear squeegees and the stability of lifting, preventing the leakage of solder paste and the clamping design of the blade with a certain elasticity. The pressure of the squeegee, the lifting speed, the printing speed, and the printing range are all software-adjustable The customer provides a variety of molding methods to adapt to the PCB boards with different tin requirements, providing customers with a good printing control platform.

5. Cleaning system

The system provides three cleaning methods: dry cleaning, wet cleaning, and vacuum, which can be used in any combination and supports manual cleaning under the production interface, reducing cleaning time and improving production efficiency.

6. Highly adaptable steel mesh frame clamping system

The advanced algorithm cooperates with the automatic clamping mechanism of the steel mesh to realize the automatic installation of the mesh frame of 800mm * 800mm and below, ensuring the rapid replacement of the model in the production process.

7. 2D Vision™ Solder Paste Printing Quality Inspection and Analysis

The HCT-P600 adopts a texture-based image recognition algorithm and a digital camera system with a high-resolution large-field telecentric lens to effectively improve the 2D detection performance of the printing press. It can quickly detect printing problems such as offset, less tin, missing printing, and continuous tin to ensure printing quality.

8. SPI&Print Closed loop technology

A specially developed common interface enables your Solder Paste Inspection Machine (SPI) to communicate with JunTo printers for information exchange. By analyzing massive data, SPI will immediately give instructions to the printing press to automatically correct the offset or Tips for cleaning the stencil.

9. StencilVision™ Technology

JunTo's unique texture-based image recognition algorithm, combined with the digital camera system inspection technology StencilVision with a high-resolution and large-field telecentric lens, is specially used to check the dirt on the solder paste at the bottom of the stencil, and automatically judges whether it is not based on the threshold set in the program. Enable wipe operation.

Product Display - High Accuracy Automatic Stencil Printer