이메일 형식 오류

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

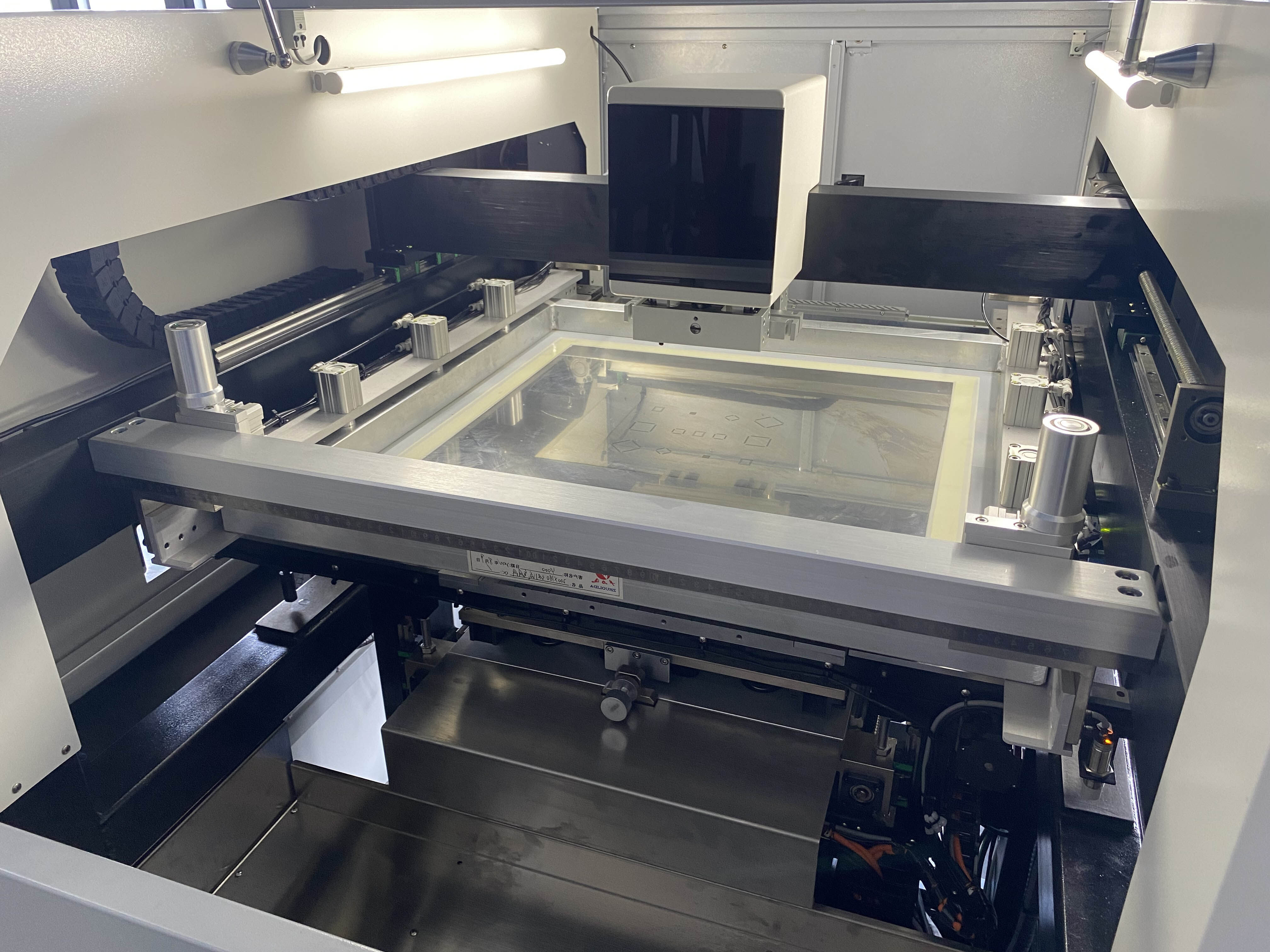

Smd Solder Paste Stencil Printer

An SMD (Surface Mount Device) solder paste stencil printer is a piece of equipment used in surface mount assembly processes for printed circuit boards (PCBs). It's a crucial component of the SMT (Surface Mount Technology) process, which is widely used in electronic manufacturing.

Here's how it generally works:

-

Preparation: The SMD solder paste stencil printer is prepared by loading a stencil. The stencil is typically made of stainless steel and is precisely manufactured with openings (apertures) corresponding to the locations of the solder pads on the PCB.

-

Alignment: The PCB is placed onto the printer's work table. It's essential to align the PCB accurately so that the solder paste is applied precisely to the pads.

-

Stencil Positioning: The stencil is positioned over the PCB. This ensures that the apertures in the stencil align perfectly with the pads on the PCB.

-

Solder Paste Application: Solder paste, a mixture of flux and tiny solder particles, is then applied onto the stencil.

-

Printing: The printer applies pressure to force the solder paste through the apertures in the stencil onto the PCB's pads. The squeegee mechanism typically used in stencil printers helps to ensure an even application of the solder paste.

-

Cleaning: Once the solder paste has been applied, the stencil is lifted away from the PCB, leaving the solder paste on the pads. The stencil may need to be cleaned thoroughly to remove any excess solder paste and ensure it's ready for the next use.

-

Inspection: After solder paste printing, it's essential to inspect the PCB to ensure that the solder paste has been applied correctly. This may involve visual inspection or automated optical inspection (AOI) systems.

Description: The SMD Solder Paste Stencil Printer is a specialized machine used in surface mount technology (SMT) assembly processes for accurately depositing solder paste onto printed circuit boards (PCBs). It plays a crucial role in ensuring precise alignment and consistent application of solder paste, which is essential for achieving high-quality solder joints during the reflow soldering process. This printer is designed to streamline the solder paste printing process, improve production efficiency, and enhance overall manufacturing quality in electronics assembly.

Key Features:

- Precise Printing Mechanism: Utilizes advanced printing mechanisms, such as squeegee or blade systems, to accurately deposit solder paste onto PCBs through a stencil.

- High-Speed Operation: Offers rapid printing speeds to optimize production throughput and meet demanding manufacturing schedules.

- Automatic Alignment: Equipped with automated fiducial recognition and alignment systems to ensure precise registration between the PCB and stencil, minimizing misalignment errors.

- Flexible Stencil Compatibility: Compatible with various types and sizes of solder paste stencils, allowing for versatility in stencil selection based on PCB design requirements.

- User-Friendly Interface: Intuitive control interface with easy-to-use features for quick setup, adjustment of printing parameters, and monitoring of printing processes.

- Vision Inspection System: Some models may include integrated vision inspection systems for real-time monitoring and verification of printing quality and alignment accuracy.

- Durable Construction: Built with robust materials and components to withstand continuous operation in industrial manufacturing environments, ensuring long-term reliability and performance.

Specifications:

- Printing Area: Accommodates PCBs of different sizes, ranging from small prototypes to large-scale production boards.

- Stencil Frame Size: Supports standard stencil frame sizes, such as 29" x 29" or 23" x 23", with customizable options available.

- Printing Accuracy: Achieves high printing accuracy with positional repeatability within micrometer tolerances.

- Printing Speed: Offers adjustable printing speeds, typically ranging from 500 to 1500 mm/s, depending on the model and configuration.

- Stencil Thickness: Compatible with stencils of various thicknesses, typically ranging from 0.1 mm to 0.25 mm, depending on solder paste requirements.

- Vision System Resolution: Provides high-resolution vision systems for precise inspection and alignment, with resolutions ranging from 5 to 20 micrometers.

Benefits:

- Improved Quality: Ensures consistent and precise solder paste deposition, leading to high-quality solder joints and reliable electronic assemblies.

- Increased Productivity: Enhances production efficiency and throughput by automating the solder paste printing process and minimizing setup time.

- Cost Savings: Reduces material waste and rework associated with manual solder paste application, resulting in cost savings and improved yield.

- Flexibility: Accommodates various PCB designs and production requirements, offering versatility and scalability in manufacturing operations.

- Process Control: Provides real-time monitoring and control of printing parameters, enabling process optimization and quality assurance.

Applications:

- Electronics Manufacturing: Used in SMT assembly lines for solder paste printing on PCBs in the production of electronic devices, including consumer electronics, automotive electronics, medical devices, and industrial equipment.

The SMD Solder Paste Stencil Printer is an indispensable tool in modern electronics manufacturing, offering precision, efficiency, and reliability in solder paste application. With its advanced features and capabilities, this printer helps manufacturers achieve consistent and high-quality solder joints, ensuring the reliability and performance of electronic assemblies.

Product Overview: Our SMD solder paste stencil printer is engineered to meet the demanding requirements of modern electronics manufacturing. It features a robust frame and precision components that enable precise alignment and uniform deposition of solder paste onto PCB pads. Equipped with advanced control systems and intuitive interfaces, our stencil printer offers programmable settings for stencil positioning, squeegee pressure, and printing speed, allowing for customization to meet specific production needs. Whether you're producing prototypes, small batches, or high-volume runs, our stencil printer delivers consistent results with exceptional accuracy and repeatability.

Features:

- Precision Printing: Our stencil printer ensures precise deposition of solder paste onto PCB pads, minimizing solder bridging, misalignment, and other common defects associated with manual or less precise printing methods.

- User-Friendly Interface: With intuitive controls and user-friendly interfaces, our stencil printer is easy to set up, program, and operate, reducing the need for extensive training and ensuring quick ramp-up times for operators.

- Versatile Compatibility: Our stencil printer is compatible with a wide range of stencil sizes and PCB layouts, making it suitable for various board sizes, component densities, and production requirements.

- Adjustable Settings: The printer allows for adjustable settings such as stencil tension, squeegee pressure, and printing speed, providing flexibility to optimize printing parameters for different solder paste types, board designs, and production environments.

- Reliable Performance: Engineered for durability and reliability, our stencil printer is built to withstand the rigors of continuous production, delivering consistent performance and high-quality printing results over time.

Why Choose Us:

- Quality Assurance: We are committed to delivering high-quality stencil printers that meet the strictest standards of performance, reliability, and durability.

- Technical Support: Our experienced team provides comprehensive technical support, including installation assistance, training, troubleshooting, and ongoing maintenance services, to ensure optimal performance and uptime for your production line.

- Customization Options: We offer customization options to tailor our stencil printers to your specific production requirements, including optional features, accessories, and upgrades to enhance functionality and performance.

- Cost-Effective Solutions: Our stencil printers offer excellent value for money, providing efficient and reliable printing capabilities that help optimize production efficiency and reduce manufacturing costs.

- Customer Satisfaction: We prioritize customer satisfaction and strive to exceed expectations by delivering innovative solutions, responsive service, and dependable support to meet your needs and exceed your goals.

Conclusion: Invest in our SMD solder paste stencil printer to optimize your surface mount assembly process and achieve superior results in electronics manufacturing. Contact us today to learn more about our stencil printer offerings and discover how we can help streamline your production processes and enhance your competitive advantage in the industry.