이메일 형식 오류

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

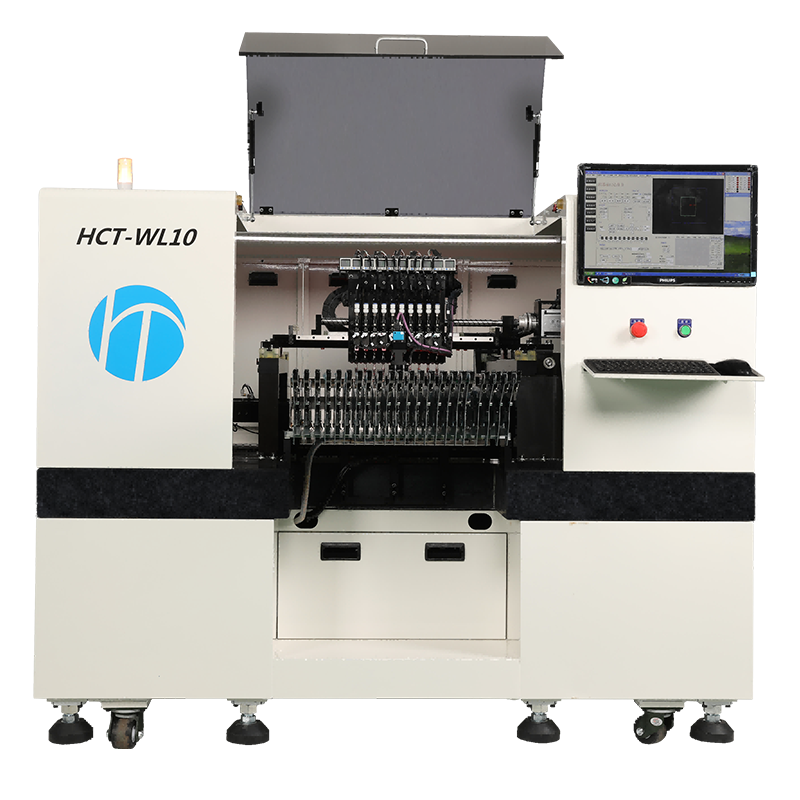

HCT-550LW Automatic 10 Heads LED Placement Machine

Experience the power of advanced LED placement technology with our HCT-550LW automatic 10 heads LED placement machine.This cutting-edge machine is designed to provide high-precision and high-speed placement of LED components, making it an essential tool for LED manufacturing processes.

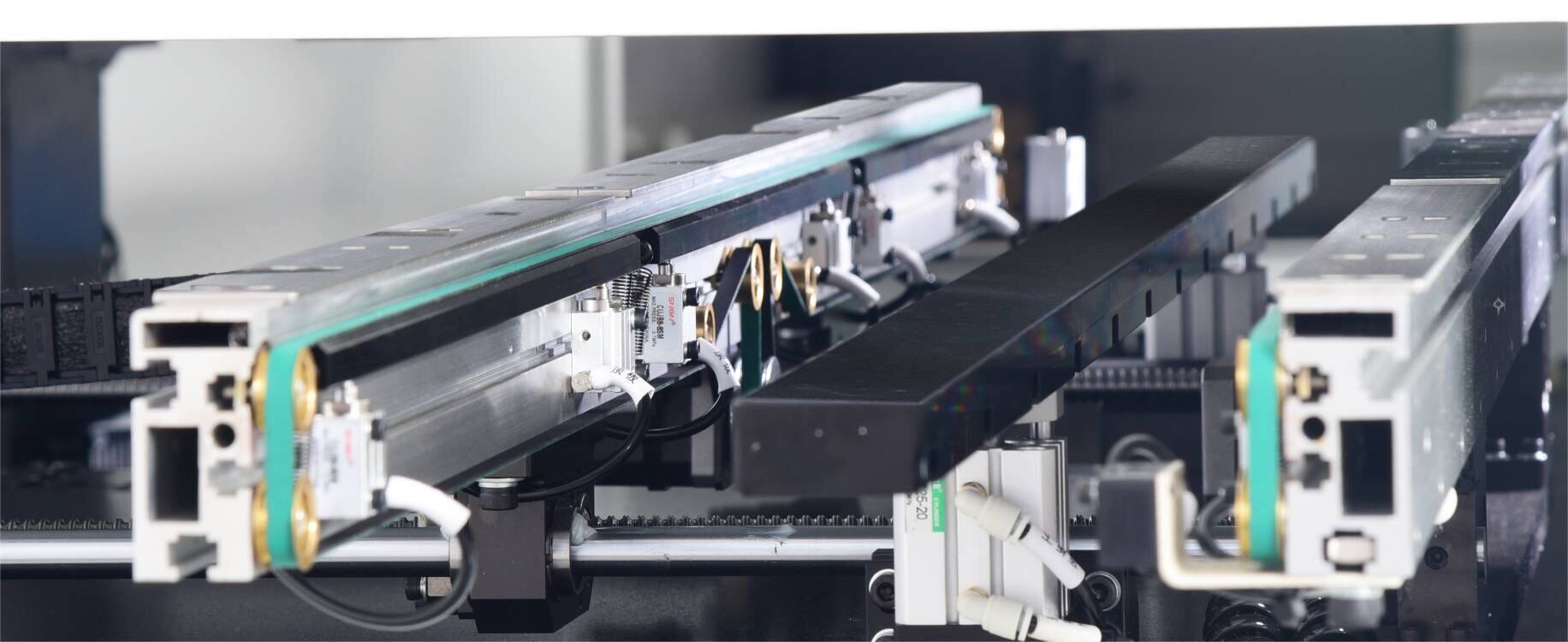

This machine is equipped with a Flying Vision Alignment System, featuring bottom fixed cameras for accurate component placement. With 10 spindles and a single gantry, this machine offers efficient and precise LED component placement.With its high accuracy, high speed, and automatic nozzle change function, this machine offers exceptional performance and efficiency in LED component placement.

P&P Machine Standard Spare Parts List:

Electric Feeder 8MM - Qty: 10

Samsung Nozzles - Qty: 30

Hexagon Wrench Tool - Qty: 1

Material Rack - Qty: 1

Product Features

- High Accuracy: The machine is equipped with 5 high-definition digital vision alignment cameras, ensuring precise on-the-fly mode placement. This guarantees the accuracy and quality of LED component placement.

- High Speed: With a maximum placement speed of 0.065s/chip, the HCT-550LW ensures efficient and fast production processes. This allows for increased productivity and reduced manufacturing time.

- Automatic Nozzle Change: The machine features an automatic nozzle change function, enabling seamless and efficient placement of different sizes of components. This eliminates the need for manual nozzle changes, saving time and effort.

- SMEMA-Compatible Inline Conveyor: The HCT-550LW comes with a SMEMA-compatible inline conveyor, allowing for easy integration into existing production lines. This enables automated and streamlined production processes.

Specification

|

Model |

HCT-550LW |

|

|

Alignment |

Flying Vision Alignment System (Bottom Fixed Cameras) |

|

|

Number of Spindles |

10 Spindles x 1 Gantry |

|

|

RatedPlacement Speed |

Vision Alignment |

LED 2835 55,000 CPH (Optimum) |

|

Placement Accuracy |

±0.05mm (Based on the standard chips) |

|

|

Mechanical Precision |

±0.02mm |

|

|

Component Range |

Fly Camera |

0603(inch)~5050~7474(mm), high-power LED,IC<10mm |

|

Max Height |

H=18mm |

|

|

Board Dimension(mm) |

Minimum |

50(L) x 50(W) |

|

Maximum |

1200(L) x480(W) 1500(L) X 480(W) Optional |

|

|

PCB Thickness |

0.5 - 3.0 |

|

|

Board Handling Method |

Inline Conveyor |

|

|

Tape Feeder |

Feeder Type |

ElectricFeeder |

|

Feeder Capacity |

26 (12mm Standard) |

|

|

Optional |

8mm, 12mm, 16mm, 24mm |

|

|

Utility |

Power |

AC 220V/240V 50/60Hz, Single phase |

|

Max3.5KW |

||

|

AirSupply |

Built-in Vacuum Pump (for nozzles only) |

|

|

Mass |

Approx.1700kg |

|

|

External Dimension(mm) |

2,050(L) x1,350(D) x 1,360(H) |

|

Product Advantages

1.Versatile Component Range: The machine is capable of placing SMD components ranging from 0603 to 7474, including LED chips, capacitors, resistors, ICs, diodes, and odd-shape components. This versatility makes it suitable for a wide range of LED lighting products.

2.Accommodates Various PCB Sizes: The HCT-550LW can handle PCBs with dimensions ranging from 50mm x 50mm to 1200mm x 480mm. This flexibility allows for the assembly of various LED PCBs, including flexible PCB strips, circular LED light bulb boards, and irregularly shaped boards.

3.Excellent Hardware Support: The machine is built with high-quality hardware components from renowned international brands. This ensures placement repeatability, precision, and durability, resulting in reliable and consistent performance.

4.User-Friendly Software: The HCT-550LW features self-developed software that simplifies production processes, making it easy to operate and program. This user-friendly interface enhances efficiency and reduces the learning curve for operators.

Product Display